Subtotal: $ 525.54 USD

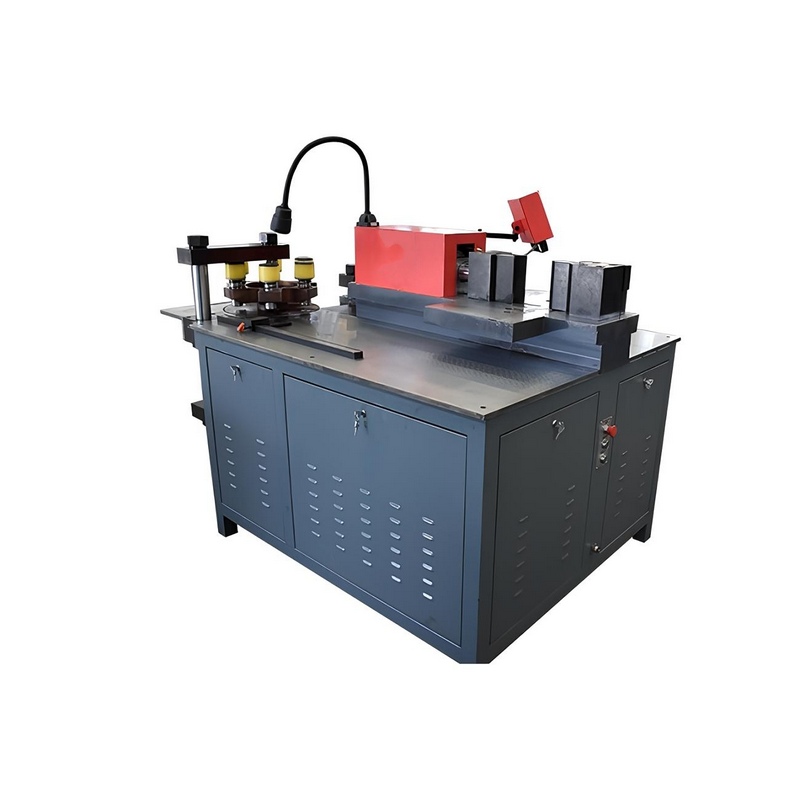

SMG 8000XA NC Three in One Busbar Processing Station

The SMG 8000XA NC Three In One Busbar Processing Station is designed to perform punching, shearing, and bending as well as many other supposed operations required to complete your processing needs.

The cleaver design allows set-up flexibility streamlining the processing both boosting production efficiency and reducing handling time significantly. The bending unit is equipped with a quality PLC control system ensuring precision and stability when processing copper and aluminium busbars of varying specifications.

$ 22,514.98 USD

The SMG 8000XA NC Three in One Busbar Processing Station is designed to perform punching, shearing, and bending as well as many other supposed operations required to complete your processing needs.

The cleaver design allows set-up flexibility streamlining the processing both boosting production efficiency and reducing handling time significantly. The bending unit is equipped with a quality PLC control system ensuring precision and stability when processing copper and aluminium busbars of varying specifications.

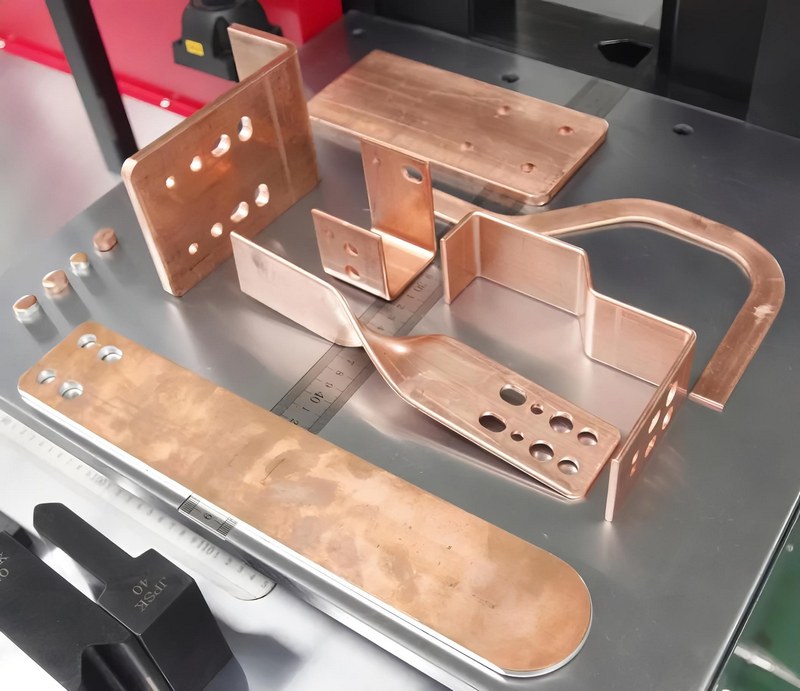

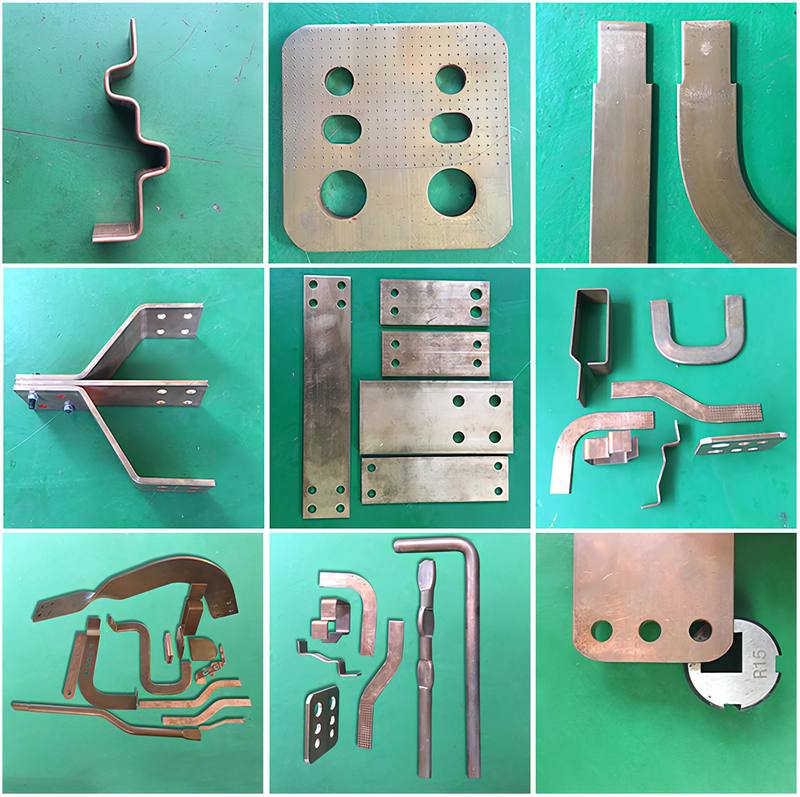

The user-friendly operator panel increases productivity, the processing station is capable of shearing, punching (circular and oblong holes), flat/vertical bending, and knurling copper and aluminium busbars.

With specialised tooling, the busbar machine can also perform flat pressing, embossing, cable connector processing, cutting, flat crushing and other operations for custom application requirements.

Main Features of SMG 8000XA NC:

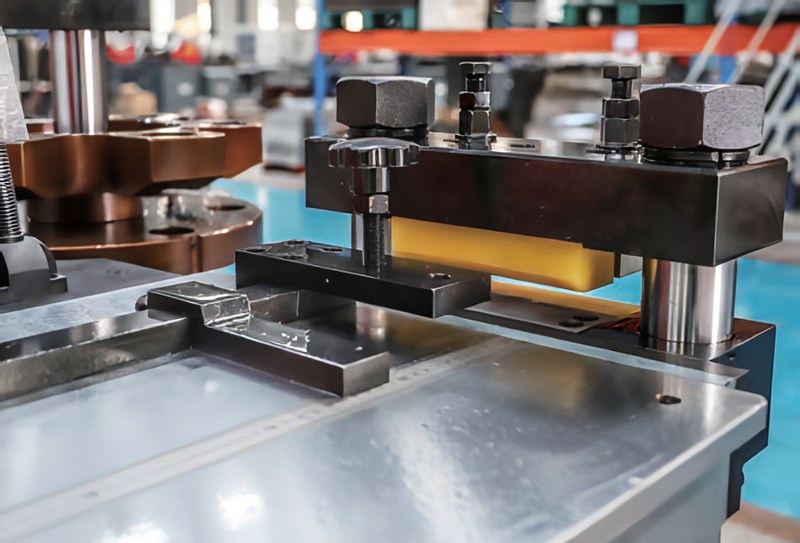

- Superior Shearing Capabilities:

- Our innovative shearing station design delivers consistently precise bur-free cutting, enhancing both the look and quality of your work and minimalising material waste.

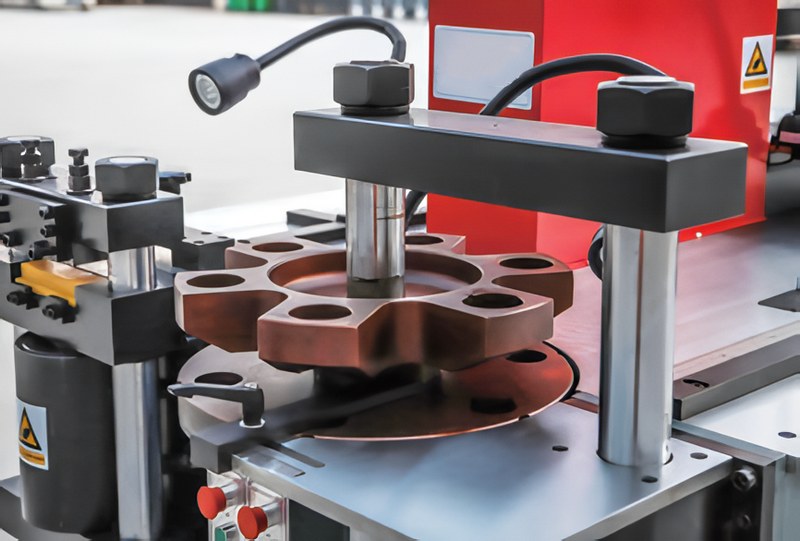

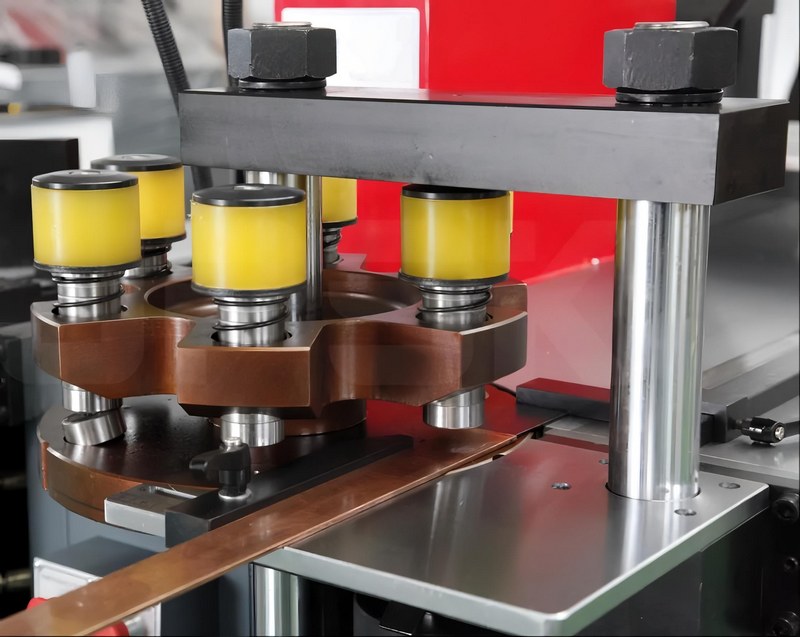

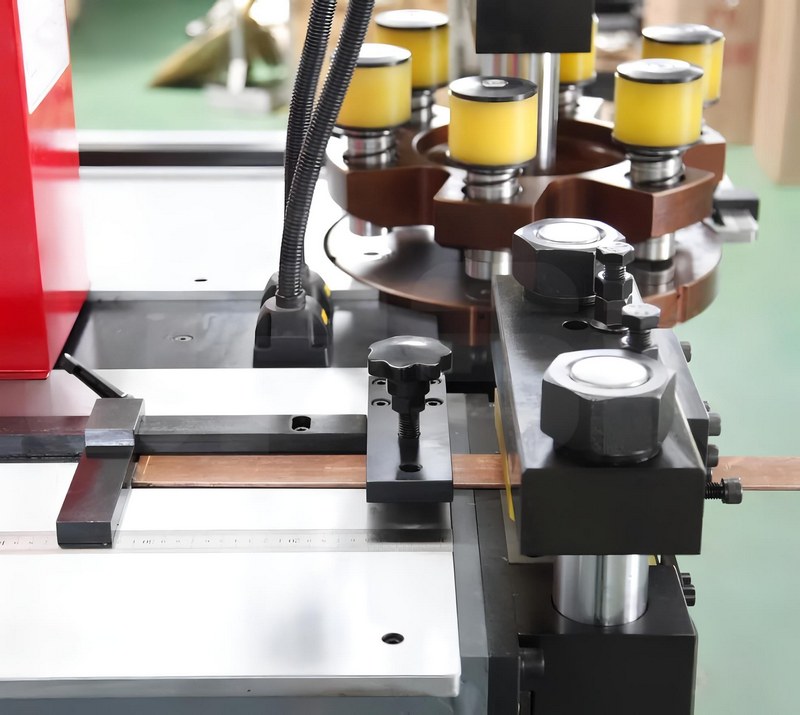

- Indexable Punching Unit:

- The integration of an indexable tool carousel enhances the machine’s user-friendliness and significantly amplifies productivity. This results in a notable reduction in operator setup time and errors, promoting a more efficient operational environment.

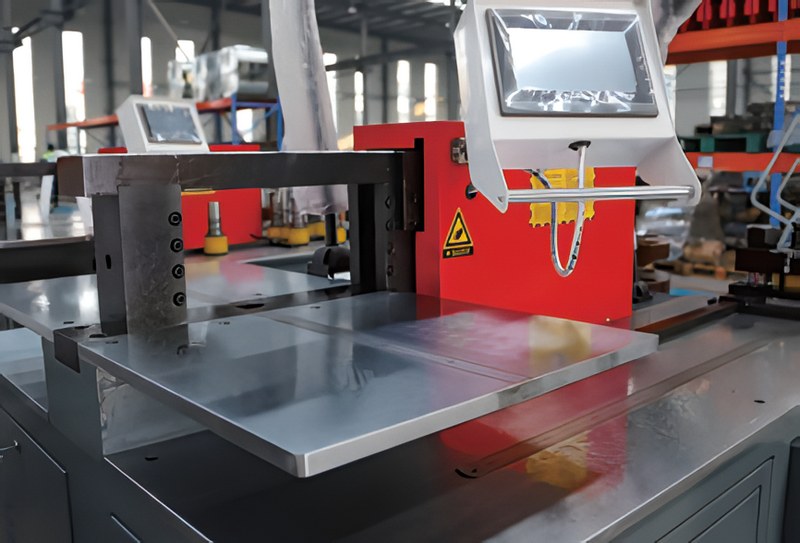

- Intelligent Bending Precision:

- You can easily adjust for flat or vertical bends using the NC controller’s touch screen. Plus, precise specifications can be inputted such as busbar thickness, angles, or complex bends like Z bending with an accuracy of ±1 degrees

- Using a two-level work table allows for working on three positions at once.

- Smart NC Control Data Management:

- The NC controller utilises pre-inputted historical data to produce reusable program data, ensuring precision and uniform quality for all future batches.

The SMG 8000XA NC Busbar Processing Station is more than just equipment; it symbolizes an investment in precision, efficiency, and adaptability. Tailored to meet modern processing demands, it caters to those seeking to transition from slow, traditional methods to the swift, precise, and seamless era of busbar processing.

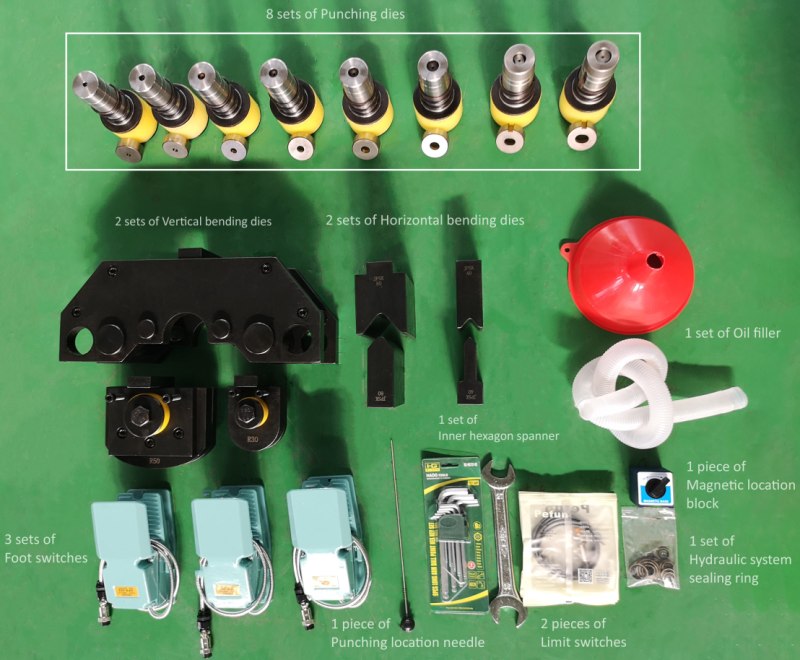

Standard Accessories

Punching Dies:

|

8 sets |

| Horizontal bending dies | 2 sets (4pcs) |

| Vertical bending dies | 2 sets (3pcs) |

| U shape bending die (SMG-8000XA NC without U-shape bending) |

1 set |

| Oil filler | 1 set |

| Inner hexagon spanner | 1 set |

| Hydraulic system sealing ring | 1 set |

| Foot switches | 3 sets |

| Limit switches | 2 pieces |

| Punching location needle | 1 piece |

| Magnetic location block | 1 piece |

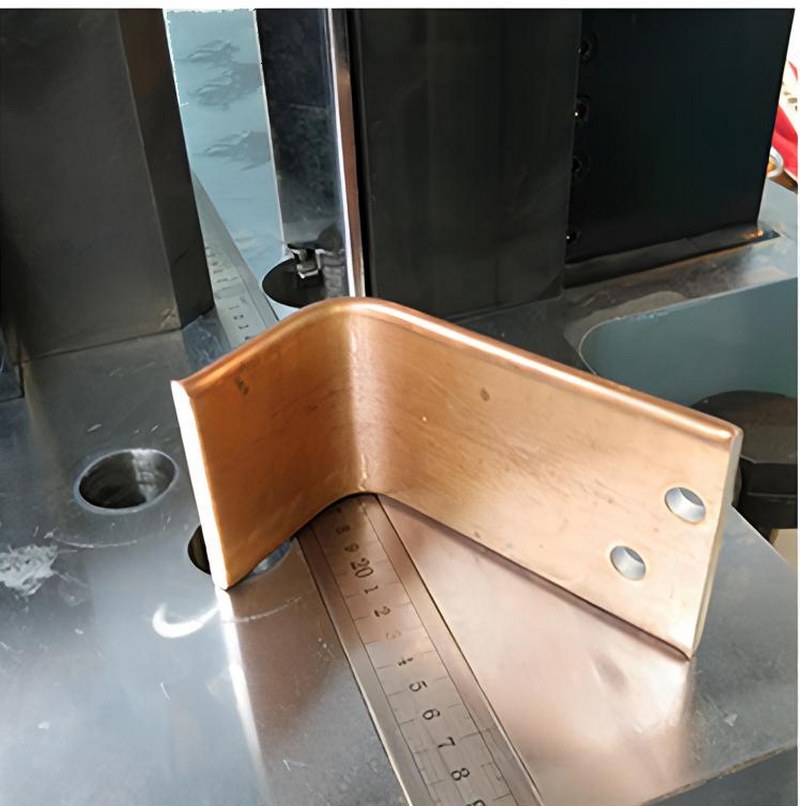

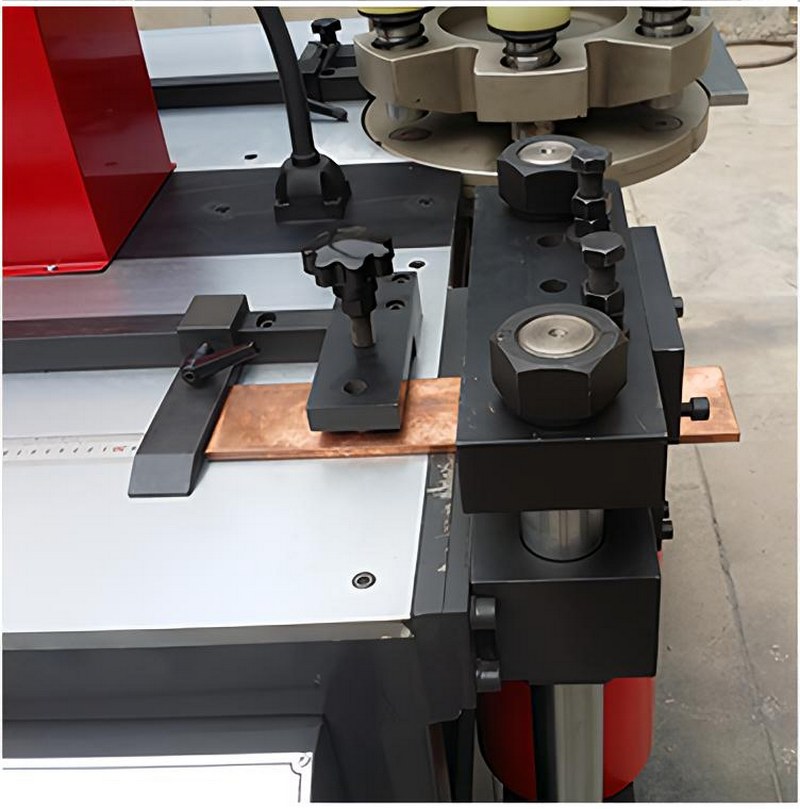

SMG 8000XA NC Sample Process:

Processing Details:

SMG XA NC Series Three in One Busbar Processing Station Video

Specification

| Model | SMG 8000XA NC |

| Nominal force | 800 kn |

| Punching diameter range |

Ø 4.3 – Ø 34 mm

|

| Max. thickness | 20 mm |

| Max. width | 250 mm |

| Max. shearing thickness | 20 mm |

| Max. shearing width | 250 mm |

| Max. horizontal bending width | 800 mm |

| Max. Horizontal bending thickness | 20 mm |

| Max. vertical bending size | 10 x 120 mm |

| Power | 3 x 5.5 KW |

| Bending precision | =+ 1 ° degree |

| Repeat bending precision | =+ 0.5° degree |

| Supply Voltage | Three Phase 415vac |

| First table size | 1920 x 1385 mm |

| Second table size | 985 x 500 mm |

| Outside dimension |

1950 x 1560 x 1450 mm

|

| Container size |

2060 x 1660 x 1650 mm

|

| Weight | 2100KG |

Based on 0 reviews

Only logged in customers who have purchased this product may leave a review.

Related products

-

Beveling Machines, Plate Edge Milling Beveling Machines

SMG 70W Workshop Plate Edge Beveling Machine

0 out of 5(0)The SMG 70W Workshop Plate Edge Beveling Machine provides a high-efficient and precise performance for heavy, short and thick metal plates. It is has a wide range of clamp thickness from 8-80mm, a bevel angle of 10-75 degrees and is adjustable for easier use. Steel Machinery Group offers a wide variety of beveling machine engineered with the latest technology.

SKU: BEVELING-SMG-70W$ 29,172.35 USD -

Beveling Machines, Beveling Machine Tooling

10 x SMG Carbon Steel Internal Beveling Cutter for ISE/ISP Models

Beveling Machines, Beveling Machine Tooling

Beveling Machines, Beveling Machine Tooling10 x SMG Carbon Steel Internal Beveling Cutter for ISE/ISP Models

0 out of 5(0)SMG Carbon Steel Internal Beveling Cutter For ISE and ISP Models are always a popular choice for the ISE and ISP models of the SMG beveling product lines as it offers a more cost-effective alternative to stainless steel cutters. We have carbon steel cutters for different angle preferences and requirements. For custom specifications, contact us.

SKU: SMG-ISEISP-CS-ITB$ 139.76 USD -

Beveling Machines, Plate Beveling Machines, Handheld Bevelers

SMG PBM-15 Portable Beveling Machine

0 out of 5(0)SMG PBM-15 Portable Beveling Machine is designed for beveling and chamfering metal plate and pipe prep-welding. It is suitable for regular curved surfaces such as outer circle, inner hole, waist hole and irregular inner and outer cavity edges.

SKU: SMG-K15$ 2,492.95 USD -

Beveling Machines, Plate Edge Milling Beveling Machines

SMG Rapid-Edge 80DM Double Sided Milling Type Plate Beveling Machine

Beveling Machines, Plate Edge Milling Beveling Machines

Beveling Machines, Plate Edge Milling Beveling MachinesSMG Rapid-Edge 80DM Double Sided Milling Type Plate Beveling Machine

0 out of 5(0)The SMG Rapid-Edge 80DM Double Sided Milling Type Plate Beveling Machine is designed to provide high- quality, efficient results for plate preparations.

This machine is designed to work with a wide range of plate sizes and is fitted with an indexable rotating head for double-sided plate beveling. With an extra-large beveling capacity for 80mm plate, the maximum bevel face width is 70mm and an adjustable beveling angle from 0-60 degrees.

Capital Machinery supplies a large range of Plate Beveling Machine in Australia. We offer top-quality brands and provide quality service for all your beveling requirements.

SKU: BEVELING-SMG-RE80DM$ 12,176.94 USD

SMG Portable Work Stand

SMG Portable Work Stand

There are no reviews yet.